Principle of binary aerosol

In the current Chinese aerosol market, dual packaging is more and more sought after by the market. In fact, this technology has been mature and used in foreign countries for 30 or 40 years, and we are a latecomer. Then we collect some information, to briefly introduce the basic understanding of binary packaging.

Binary packaging English name bag-on-valve, English abbreviation BOV.

Dual packaging in the market with modern technological developments to promote the cosmetic, pharmaceutical and food industry aerosol applications. At the same time, many small fire extinguishers are also using dual packaging. Binary aerosols can be applied to liquids or viscous products, and can be applied to a wide range of applications.

What are the advantages of binary packaging?

1: easy to use, make consumers happy to use;

2: can be sprayed at any Angle as well;

3: can reach more than 99% of the ejection rate;

4: can make oxygen sensitive products and sterile products longer service life;

5: can reduce the addition of preservatives;

6: environmentally friendly projectile agent, reduce or eliminate the flammability of the product;

7: Uniform and controllable injection state can be realized

How does binary packaging work?

Binary packaging is composed of a valve bonded to the bag and aerosol cans, etc. Liquid filling in the bag, the projectile agent filling between the bag and the inner wall of the tank. When the valve is opened, the ejector squeezes the bag and extrudes the material to form atomization, emulsion, gel and other states.

1: binary packing valve

Dual pack valves can be male or female.

2: binary valve bag

It is an aluminum composite bag approved by the FOOD and Drug Administration (three or four layers depending on the requirements of the product). According to the different production can be applied to all sizes of aerosol.

3: projectile agent

Since the two-component package is separated from the product, environmentally friendly ejectors such as compressed air, nitrogen, etc. can be used, eliminating the need for combustible ejectors.

4: nozzle

According to different products, can choose a variety of nozzle

5: dual packaging aerosol cans

Both aluminum and tin cans can be used (aluminum cans are preferred here). Jars of all shapes can be used.

6: the outer cover

A variety of aerosol standard caps can be used.

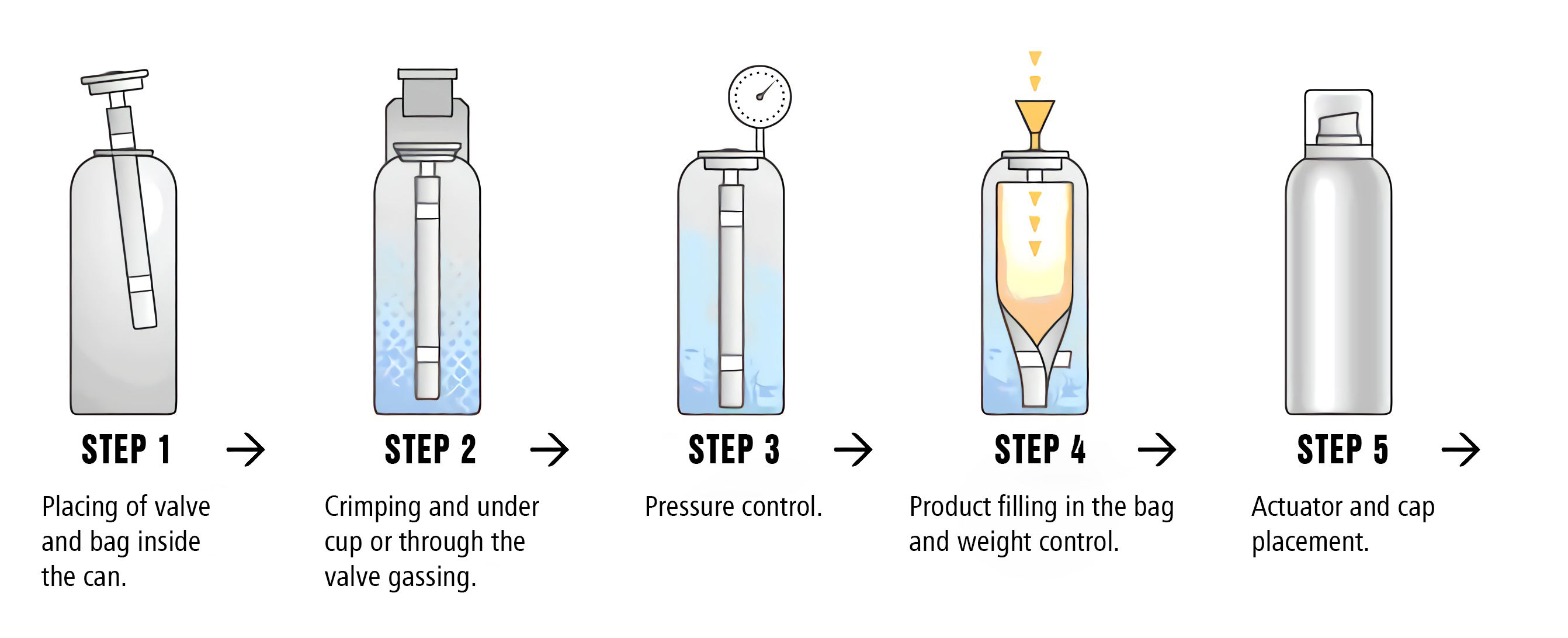

Dual aerosol filling process

The filling sequence of binary packaging is different from that of our ordinary one-yuan aerosol. The filling sequence of our general aerosol is canning material first, then canning gas, while the filling sequence of binary packaging is just the opposite, canning gas first, then canning material, as shown below:

The pressure design, airtight stability, the degree of opening of the bag during filling, and the corrosiveness of certain material and liquid to aluminum are the key factors for the stability of the finished product of binary packaging.

At present, for binary aerosol, China is in its infancy, especially the bag technology and filling technology as well as some corresponding regulations and standards need further breakthroughs and the accumulation and promotion of technical experience!

Wish China binary aerosol better and better!

Post time: Mar-04-2022