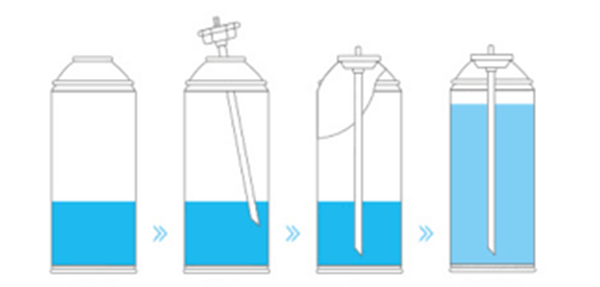

Aerosol cosmetics have two kinds of packaging forms, Must include, Bag-on-Valve these two kinds of packaging using filling methods have certain differences, specific filling methods and advantages and disadvantages.

Must include advantages:

1. The production process of packaging is very mature and widely used. In addition to spray, sunscreen and gel can be used. And the material of the bottle body is not too big requirements, aluminum cans, plastic can.

2, the production process is simple, the price is relatively affordable.

Disadvantages:

there is precipitate, need to shake before use, need to press several times during use, the bottle body can only maintain a horizontal fixed Angle when spraying.

Bag-on-Valve advantages:

1. higher safety, choose 99ML capacity of aluminum cans, can take high-speed rail and aircraft.

2. material and propellant isolation, not easy to be polluted, do not need to add other preservatives, so it will not cause harm to the skin, plus the inner material atomization treatment, uniform and soft.

3, material and gas separation, no sediment, no shaking, take with spray, a smooth spray to the end, no repeated press, no dead Angle arbitrary spray, material empty rate of 99%, no waste.

4. It is lighter and more convenient to carry than ordinary spray.

Disadvantages:

Binary packaging production process is more complex, and must be aluminum cans, production cost is relatively,high production consumption.

At present, due to the advantages of dual packaging aerosol cosmetics compared with one yuan packaging, dual packaging is the trend, many cosmetics manufacturers began to research and develop dual packaging filling production lines, while driving equipment manufacturers.

Post time: Aug-05-2022